Brief introduction:

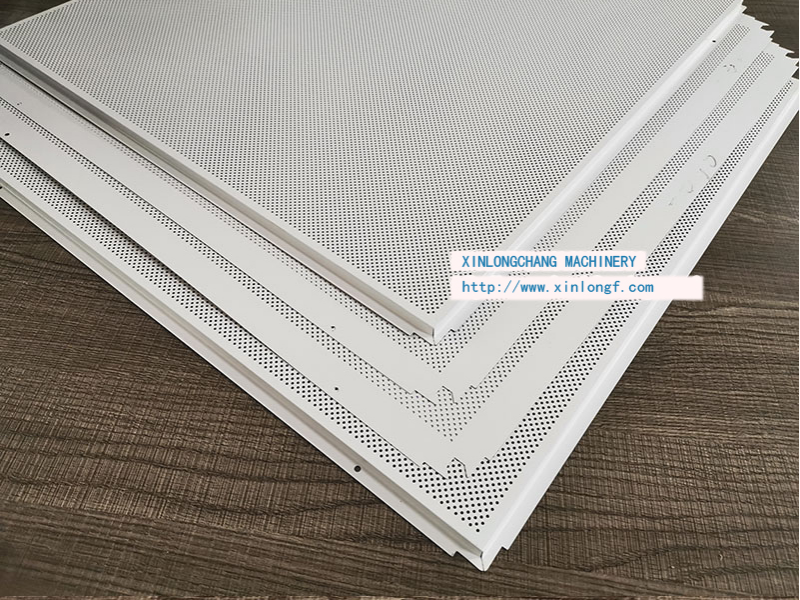

Semi-automatic line to make perforated ceiling tile 600x600mm and 600 x 1200mm, lay-in and clip-in by changing mold.

The entire line combined by decoiler, leveler, power press machine and punching mold, servo feeder, corner cutting, forming, transport belt, stacker

The PLC, servo motor are mainly from Japan, and partly from Germany, to make the machine run without errors or problems.

1, Decoiler

A. Decoiler inner diameter 480-550mm

B. Carrying capacity 5 tons

C. Hydraulic inner tighten power 3kw

2. leveler

A. 10+11 leveling rolls,

B. Rolls diameter 58mm

C. Rolls material: 45Cr heat treatment, and Chrome coating

D. Motor 3kw + decelerator

3, high speed power press machine 125 tons

A, speed 100-200 drops/minute

B, punching mold 4-8 lines

C, punching tools DC53

4. Servo feeder

A, feeding rolls 90mm, mid-frequency treated and chrome coating

B, servo motor 1.8kw, Japan

C, feeding tolerance 0.2mm

5, hydraulic corners cutting machine

A, pressure 60 tons,

B, frame 4 posts

C, cut four corners and cut to length on same machine

6, leveler no.2

A, leveler to make steel/aluminum panel flat after punching

B, levelling rolls 10+11, diameter 40mm

7, conveyor belt

To move the cut pieces to next step

8, stacker:

To collect perforated and cut aluminum/steel sheets

9, hydraulic press forming machine

A, pressure: 140 tons

B, two sets: one for 600x600mm and one for 600x1200mm

C, structure: steel welded, four posts

10, conveyor belt

Move the formed ceiling tiles out from forming machine

11. punching and forming mold list:

A, perforating holes punching mold

B, perforating holes punching mold spare, same one

C, lay-in profile corner cutting and cut to piece mold

D, clip-in profile corner cutting and cut to piece mold

E, 600x600 lay-in forming mold

F, 600x1200 lay-in forming mold

G, 600x600 clip-in forming mold

H, 600x1200 clip-in forming mold

12, major parts:

PLC: Japan

Screen: Delta

Switches: omron

Servo motor: Japan

Frequency: Delta

Decelorator: Delta

Motors: taiwan

Air pump: zhejiang